I have been a seamless knitter from the start, and I’ve often heard statements like “seams add structure” and “seamless knits will stretch out of shape.” As with most things, it depends. If you knit a garment at a loose gauge in a yarn with no memory it will probably stretch out of shape with or without seams. If structure and rigidity are what you want, hand knitting may not be the best method for creating your garment. Although you can create knit fabrics with more structure by working stranded colorwork or a slip-stitch pattern at a dense gauge, you may consider creating your garment out of a stiff woven fabric instead.

Knit fabric is very flexible and fluid and can be shaped 3-dimensionally as the fabric is created. Rather than seeing the flexible property of knit fabric as an obstacle to overcome, I look at it as an advantage to be utilized. Knit fabric looks the same whether it is worked flat or circularly (unlike crocheted fabric) and pieces can be joined invisibly (unlike woven fabric). Seams alone will not make knit fabric behave like woven fabric, but it’s not true either that seamless knits will always stretch out of shape over time. Well-fitting, thoughtfully constructed knit garments will be both comfortable and flattering for years of wear, and constructing whole garments without a single seam is like magic!

The most crucial aspect of garment construction is the way the sleeves fit into the shoulders of a garment. This section of a garment can be referred to as the yoke, regardless of construction. Most construction methods can be worked seamlessly from the top down or the bottom up, simply by swapping increases for decreases. The main types of shoulder and sleeve constructions are: drop shoulder, raglan, round yoke, and set-in sleeve. In this post I’ve listed the characteristics of each one, and common problems to look out for when knitting and designing them.

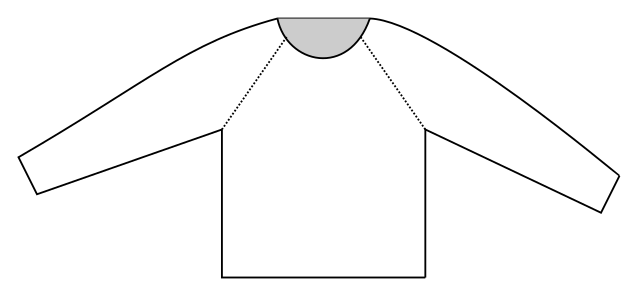

Raglans

Raglan yokes have a characteristic diagonal line between the shoulder and sleeve join. Although top-down raglans have become very popular, raglans can also be made seamlessly from the bottom up, or in pieces and seamed. It’s the diagonal join that makes it a raglan. The standard increase or decrease rate for a raglan yoke is 8 stitches every 2 rows or rounds; 2 stitches at every raglan line. This ratio works well for sizes with a chest circumference of around 40″/100 cm but will result in armholes that are too deep and neck circumferences that are too wide in larger sizes. Smaller sizes can have the opposite problem. To create a better fitting raglan a faster rate of increase, like 12 or 16 stitches for every 2 rows/rounds, can be used at the top to ease over the shoulders and at the bottom to curve around the underarms. If your size does not fall in the middle of the size range look for this type of saddle/raglan hybrid for a better fitting sweater.

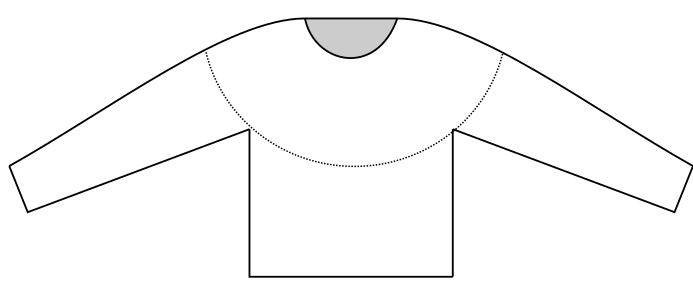

Round Yokes

This is a great construction for people with a non-standard bust-to-upper-arm ratio because there is no distinction between body and sleeves until the bottom of the yoke. Stitches can be borrowed from the body and moved to the sleeves for larger arms, or vice versa to accommodate a larger bust. Round yokes are shaped with several sets of increase or decrease rows or rounds, or sometimes in wedges. The shaping rounds should be more frequent near the neck opening to accommodate the width of the shoulders, with most of the shaping rounds occurring in the top half of the yoke. If the shaping rounds are evenly distributed throughout the yoke it will result in a cone-shaped yoke, causing the sweater to ride up at the neck because the circumference of the fabric isn’t large enough to fit around the shoulders.

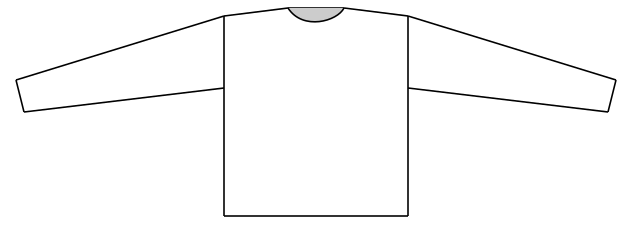

Drop Shoulders

The drop shoulder is a really simple construction that’s great for oversized or unisex sweaters. The shoulder line is meant to fall at the upper arm, not the shoulder break, so this style will work well for people with broad or narrow shoulders without any adjustments. One problem you might encounter with this style is sleeves that are either too long or too short. The top of the yoke forms part of the sleeve, so the length of the sleeve depends on how far down the arm the shoulder extends. Knitting the sleeves directly onto the sweater by picking up stitches around the armhole allows the sweater to be tried on and the sleeve length adjusted for a perfect fit.

Set-In Sleeves

Set-in sleeve construction follows the shape of the body more than the other styles. To get a really good fit the line where the sleeve is set into the shoulder should fall right at the shoulder break; where the shoulder bends when you extend your arm to the side. Because of this, it’s best to choose your size based on your shoulder width rather than chest circumference, and then make adjustments for the difference. Casting on extra stitches at the front neck when working from the top down, or decreasing additional stitches at the front neck when working from the bottom up can create extra fabric at the chest to accommodate a larger bust and narrow shoulders.

Seamless set-in sleeve yokes can be worked in one piece from the bottom up or top down using decreases or increases to shape the sleeve cap and armhole simultaneously, or the front and back of the yoke can be shaped first with stitches picked up around the armholes and shaped with short rows to create the sleeve caps. Both methods can create a set-in sleeve yoke with a smooth shoulder and sleeve join that follows the curve of the shoulder joint and the underarm.

I hope that this overview will inspire you to create seamless sweaters that fit your unique body shape and proportions, and embrace the inherent properties of knit fabric! What is your favorite sweater construction? Is there a particular modification that you always make to help your sweaters fit better? Please leave a comment!

Thank you for knitting!